Corghi Artiglio MasterCode Visual L Tire Changer

Half a century since the invention of the Artiglio and eleven years since the introduction of “Leva la leva” (leverless) technology, CORGHI sets the benchmark higher once again with the ARTIGLIO MASTER CODE.

With automatic wheel dimension acquisition enabling automatic tool positioning, and the invaluable Smart Corghi System demounting procedure, the MASTER CODE rewrites the rule book for tire changers, demonstrating once again Corghi’s unrivalled ability to continuously steer the evolution of the sector.

The goals set for these new machines were to achieve an even higher degree of automatism, to increase performance and efficiency with all wheel types and to reduce the use of that increasingly precious commodity - time. The computerised Touch Screen system guides the operator through all procedures and suggests the best possible solution to any problem encountered.

MASTER CODE is compatible with all tire types, from Run Flat-UHP tires to both small and large balloon tires. This latest creation from CORGHI - THE ONLY INNOVATOR IN THE TIRE CHANGER SEGMENT - makes work safer, simpler and quicker for the tire service professional while ensuring total protection for the rim and tire.

Wheel Data Self-Acquisition

- Self acquisition of wheel dimensions

- Automatic tool positioning

- Intelligent and very user friendly

- Three wheel type settings

- Quick

- Safe

- Ergonomic

- AUTOMATIC or MANUAL work cycle selection

Smart Corghi System

- Smart Corghi System demounting procedure

- Minimised tire stress

- Absolutely NO contact with rim!!!

- Automated, synchronised tire demounting and mounting

Dual Bead Breaker

- Dual pneumatic bead breaker penetrator

- Maximum rigidity

- Maximum efficiency and precision

- Dual opposed bead breaker discs with separately

- Controlled cylinders

Automatic Direct Lubrication

- Automatic direct lubrication of lower and upper bead

- Direct lubrication during dynamic bead breaking ensures maximum efficiency even with most stubborn tires

Mobile Control Console

- Total control in all manual operations

- Freely adjustable mobile control console

- Simple, quick and intuitive controls

- Extreme user friendly manual cycle

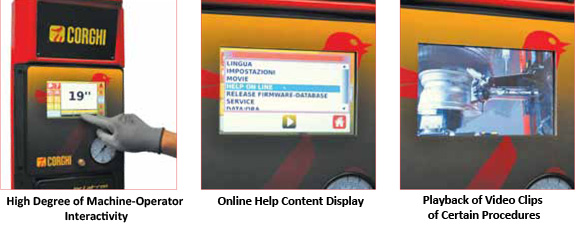

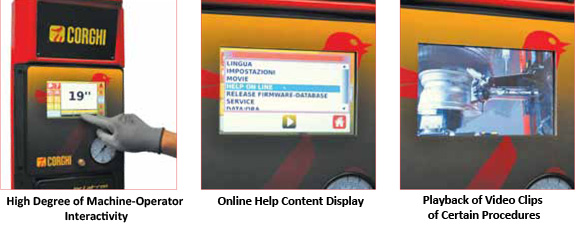

Interactive Touch Screen

- Interactive multifunctional TFT-LCD TOUCH SCREEN interface with microprocessor control

- USB port for software databases update, and for loading files and videos

- Playback capability for demonstration videos

- Scheduled maintenance reminder, self-diagnosis, sensor state check and fault indication

- Online help with instruction manual and special procedures (WDK, BSR, RFT, UHP)

Intelligent Electromechanical Turntable

- Intelligent electromechanical turntable

- New patented wheel clamp system

- Fast

- Simple

- Reliable for all wheel types

(comes equipped with additional specific flanges)

Integrated Lifter

- Integrated fully articulated lifter with 85 Kg max. load capacity

Bead Depressor

- Bead depressor with adjustable working height

- Depressor shape ideal for RFT tires

- WDK homologated

Latest Generation Inverter Motor

- Second speed also available in reverse rotation mode

- Torque control

- Controlled acceleration curve to safeguard tire

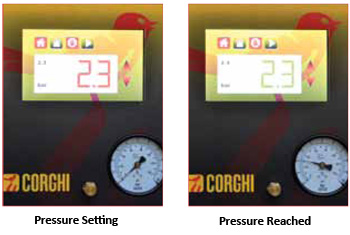

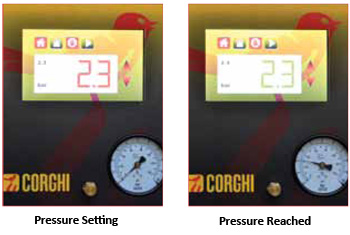

“Inflatron” Electronic Inflator

- Integrated, automated inflation and deflation system

- Permits automatic inflation of tire while operator performs other operations for optimised time use

- Overpressure inflation for bead insertion

- Touch screen user interface

- Bar, PSI and kPa scales

- End of cycle indicator

Video camera

- Video camera with image recallable from screen at any time during work

- Video camera activatable during operations, positioned for a clear view of the lower side of the tire